The KP-C system reduces the risk of fires and eliminates the need for regular duct and cleaning.

The KP-C system will effectively break down the oil and fat in the air thereby removing the odor from the exhaust air. The documented odor reduction will allow restaurants to look for premium location in odor sensitive areas. With a properly dimensioned system you can exhaust air in parking cellar, directly on street level or on to the balcony of your neighbor.

JIMCO’s Kitchen Pollution Control System (KPC) is the only system in the world with an Environmental Technology Verification (ETV), and the system has been used for commercial kitchen for over 20 years.

Minimize the risk of fire by reducing fat, grease and oil in your exhaust air. Fire risk is easily reduced with 95% by keeping your ventilation ducts clean

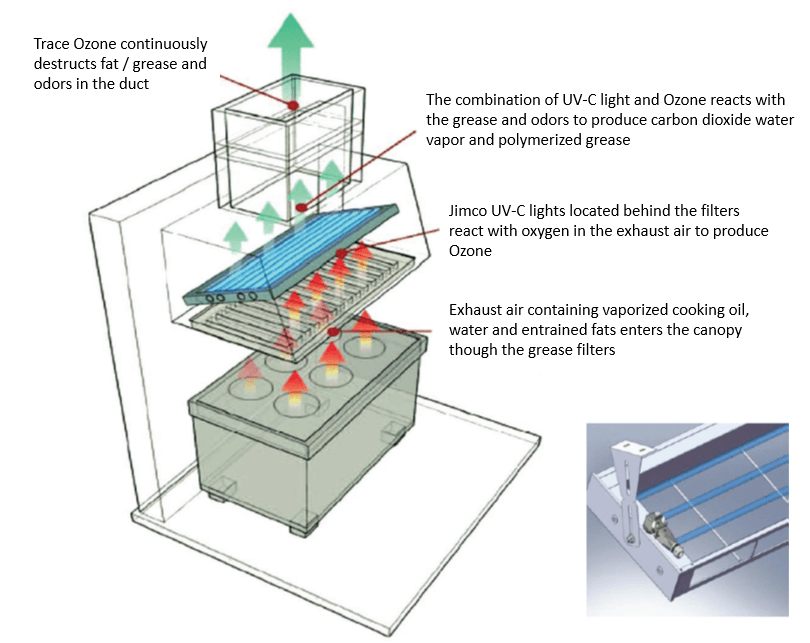

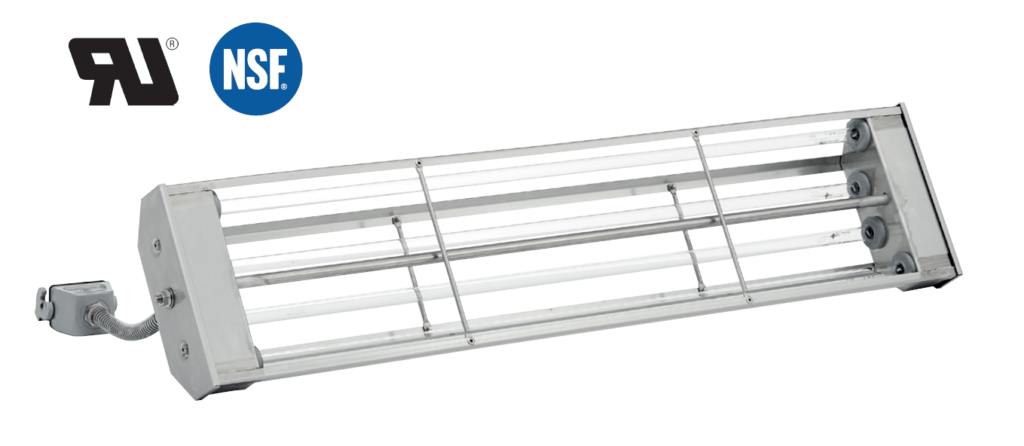

The JIMCO UV-C lamps are placed in a steel frame, which is installed behind the grease filters in the hood or, in cases where this is not possible due to lack of space, in an enclosure immediately above the hood.

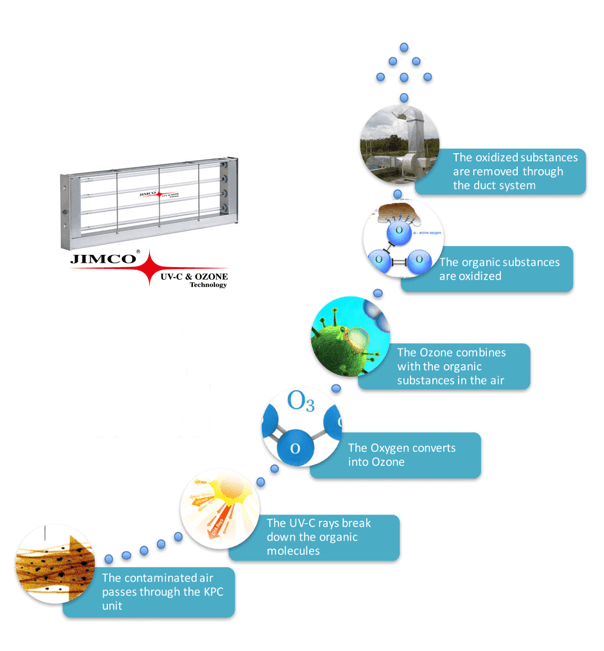

KPC inflict to intensive UV-C light on to grease particles which disrupt them and then oxidizes them through the ductwork with ozone which causes contaminants in the air to be destroyed, resulting in the reduction of odor emissions to the surroundings and no grease deposits in the ductwork. This process reduces the odor emitted to the surroundings.

We recommend that ducts are manually cleaned before installing a JIMCO commercial kitchen pollution control unit for air cleaning.

The advantages of using a JIMCO KPC system means the traditional problems with air filtration are eliminated.

Examples are: high chimneys, electrostatic filters, activated carbon filters, scrubbers, deodorizing oils etc.

Photolytic oxidation is a combination of photolysis and ozonolysis. Both processes are needed in order to obtain the wanted effect. Photolysis is a photodecomposition process and is the effect of the UV-C radiation. Organic molecules (e.g. fat, grease and oil) will be broken down by photons, when they are exposed to UV-C light. Ozonolysis is the oxidation process and is the effect of the natural ozone produced by the lamps.

The photo decomposed and broken organic molecules will be exposed to ozone and the ozone will make a cold incineration with the organic molecules and oxidize them. The photolytic oxidation process leaves no volatile compounds. Photolytic oxidation in the commercial kitchen pollution control unit for air cleaning is used in hoods to neutralize grease particles, grease vapors and organic compounds which are not captured by the primary filtering system

Tested and documented by an accredited institute, certified documentation, dependable system and amazing results.

And many more………….

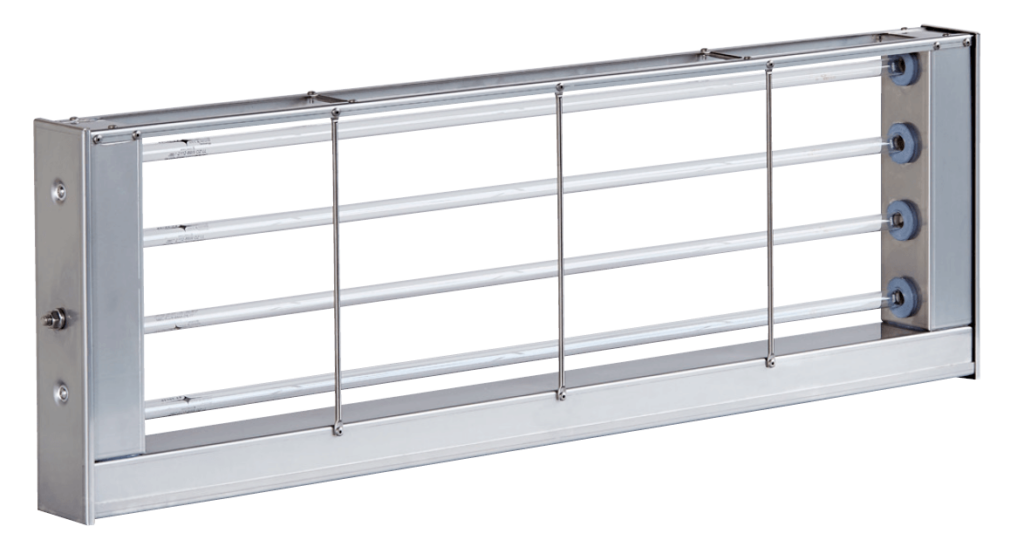

Quantity lamps 2-6

Length: 446-1714 mm

Height: 178-304 mm

Depth: 72-105 mm

Stainless steel frame available in 3 lengths, where it is possible to mount from 2 to 6 pcs. of UV-C lamps.

The ballast box is to be connected to the control board (STO). In this model, the ballast is integrated in the frame.

Quantity lamps 2-8

Length: 446-1722 mm

Height: 129-337 mm

Depth: 70-154 mm

Stainless steel frame available in 3 lengths, where it is possible to mount from 2 to 8 pcs. of UV-C lamps.

The UV-C elements must be connected to an external ballast box which secures that the lamps turn on and off correctly. The ballast box will be connected to the control board (STO).

Quantity lamps 2-6

Length : 920-1765 mm

Height: 135 mm

Depth: 222 mm

Stainless steel frame available in 3 lengths, where it is possible to mount from 2 to 8 pcs. of UV-C lamps.

The UV-C elements must be connected to an external ballast box which secures that the lamps turn on and off correctly. The ballast box will be connected to the control board (STO).

Quantity lamps: 4

Length: 780-1714 mm

Height: 201 mm

Depth: 73-143 mm

Stainless steel frame available in 3 lengths, where it is possible to mount from 2 to 8 pcs. of UV-C lamps.

The UV-C elements must be connected to an external ballast box which secures that the lamps turn on and off correctly. The ballast box will be connected to the control board (STO).

Length: 428 mm

Height: 150 mm

Width: 190 mm

IP rating : IP 20

Use as ballast for KPC UV-C FRAME – LUX / TRIANGULAR / HEX

Control box with touch display. Can have slaves connected.

1x230V+PE 50/60Hz, 2300 W

Display

Width: 124,9 mm

Height: 90,4 mm

Depth: 38,8 mm

IP rating : IP 65

Box

Width : 400 mm

Height: 300 mm

Depth: 150 mm

IP rating : IP 66

STO-TOUCH UV-C system meets EN16282-8:2017

Control box.

1x230V+PE 50/60Hz, 2300W

Width: 280 mm

Height: 200 mm

Width: 60 mm

IP rating : IP 66

Control box. With Stainless Steel housing

1x230V+PE 50/60Hz, 2300W

Width: 300 mm

Height: 250 mm

Width: 80 mm

IP rating : IP 66

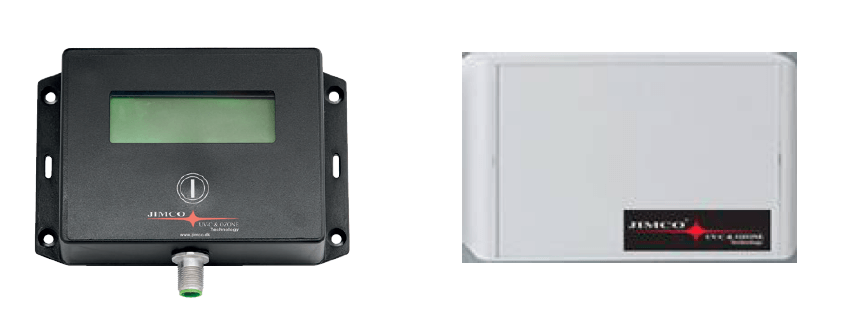

UL approved control box – File No: E499033 with remote display

1-3x230V+N+PE 50/60Hz · 6000W

Remote Display

Width: 160 mm

Height: 100 mm

Depth: 82 mm

IP rating : IP 67

Box

Width : 305 mm

Height: 250 mm

Depth: 110 mm

IP rating : IP 66

Wall mounted remote display (Plastic) + Control

1x230V+PE 50/60Hz, 2300W

Remote Display

Width: 147 mm

Height: 96 mm

Depth: 38 mm

IP rating : IP 54

Box

Width : 289 mm

Height: 239 mm

Depth: 107 mm

IP rating : IP 65

Flush remote display for hood (Steel front) + Control

1x230V+N+PE 50/60Hz · 2300W

Remote Display

Width: 150 mm

Height: 124 mm

Depth: 40 mm

IP rating : IP 54

Box

Width : 289 mm

Height: 239 mm

Depth: 107 mm

IP rating : IP 65

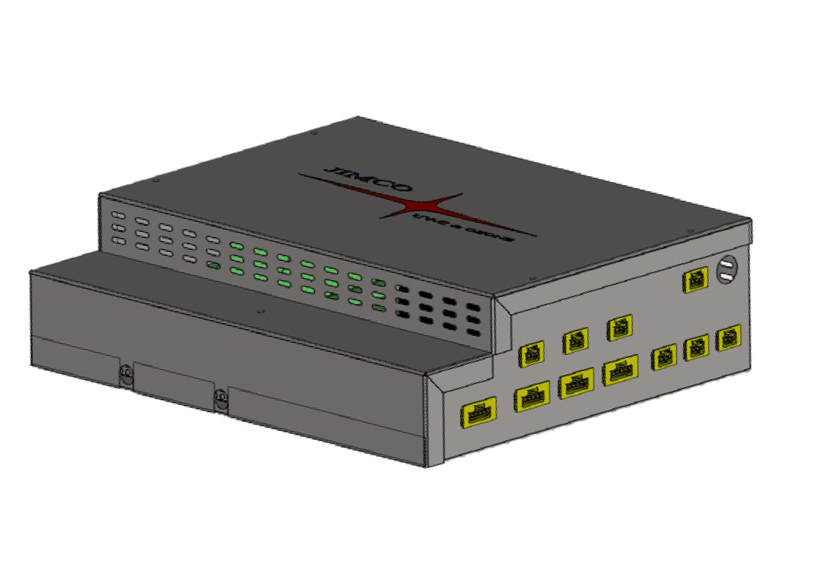

The STO-FLEX system is designed as a plug n’ play system with a touch screen for easy installation at site as modules and wiring have been done from the factory

The STO-FLEX control boxes comes with ballasts. The STO-FLEX system has one master control and with options for one Master box for maximum 1 Slave box or one Master box for maximum 3 Slave boxes. JIMCO recommends 1 box per hood section.

Optional for a system for mounting in the supply air chamber or a system with fans for mounting outside the supply air chamber.

1x230V+N+PE 50/60Hz · 2300W

Remote Display

Width: 112.5 mm

Height: 77.5 mm

Depth: 38.8 mm

Box

Width : 418 mm

Height: 357 mm

Depth: 121 mm

1x230V+N+PE 50/60Hz · 2300W

Box

Width : 418 mm

Height: 357 mm

Depth: 121 mm

Parts and lamps for Halton, Vianen, Barton, Ventco kitchen hoods